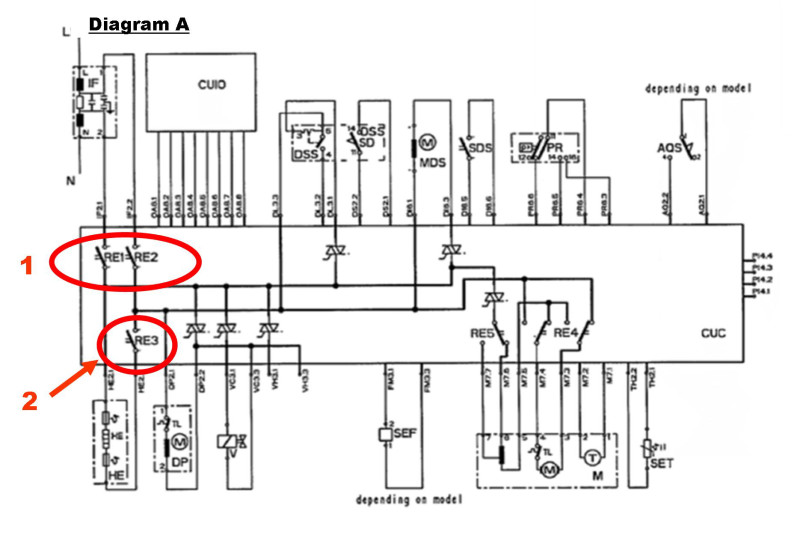

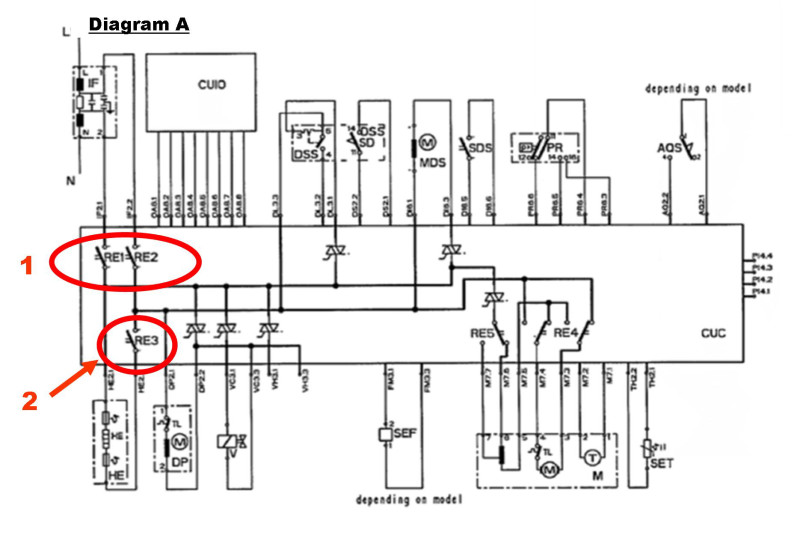

The schematic Diagram A is another Class 1 appliance in this instance a modern ‘electronically controlled’ washing machine. Unlike the kettle this appliance has far more internal components and more importantly has a more complex wiring and operating system. As before the three core mains lead connects to the appliance and in this instance passes through a suppression unit marked ‘IF’ (interference filter) before continuing on to the main control circuitry (PCB). If you look closely at the top left of the board the L & N terminals connect to two ‘Normally Open’ relay switches in circle 1 i.e. they do not ‘close’ mechanically as with a rotary or simple push On and push again for Off type mains switches. These PCB mounted ‘relay switches’ can only close when instructed to do so i.e. when a programme has been selected and the ‘start’ (low voltage) selection button is pressed. NOTE: This action ’cannot’ be carried out when using a basic PAT tester for insulation testing. Therefore an insulation test on this type of circuitry using a basic PAT tester is unable to go beyond the two ‘Normally Open’ relay switches which means that critical components such as the heating element, wash motor etc. are not tested. In such cases the applied test essentially only tests the plug, the mains lead, the suppression unit and the two wire up to the main control board. Although there are methods of compensating for this type of situation it takes knowledge of the product and additional equipment as most PAT testers are unable to test individual components (but some top end ones can).

Editors Note – Once again, in terms of depth of knowledge, consumers should be able to recognise and trust an independent standard, such as EEESafe, to ensure purchased repairs or reuse appliances carry a lower risk of an accident or an early failure occurring. This is particularly important when the item has been re-introduced from being designated as waste, tested by a protocol and uncertified Appliance Repairer. (PAS141)

There are a wide range of PAT test meters available and some are capable of applying a range of additional tests such as “Earth Leakage”, “Touch Current” and “Sub Leakage (note: this last test does not power up the appliance)” which are essentially variations of ‘Run’ testing. Such a range of test options (or not) can in itself lead to further confusion during PAT Testing or when comparing different PAT Testing equipment. Such tests essentially allow the appliance to be operated via the PAT test meter. Unfortunately this type of test on many PAT test meters is often restricted to a rather short period of time (often only a few seconds) as most PAT test meters are not designed to power appliances for extended periods of time. Such a short period time allotted for testing may not allow the door interlock mechanism to fully energise before the ‘timed’ ‘run’ period ends.

However, there are PAT test meters that ARE designed to ‘Run’ appliances for longer periods of time which can allow internal components such as the door interlock to operate. However, to ensure critical components are included in such a test appliances such as washing machines would also need to be connected to their water inlet and drainage points as it is common practice for heaters within such products to have further isolation switches that only operate at certain points of the programme sequence and/or when the appliance is filled with water. – Diagram B shows that the heater in this circuit has a normally open relay on the live supply to the heater and a switch on the neutral within the water level pressure switch.

To complicate matters even further ‘Run’ tests i.e. “Earth Leakage”, “Touch Current” etc. check for leakage of current through to the earth path and a generally accepted limit of a maximum of 3.5mA is often chosen. Unfortunately appliances such as washing machines, dishwashers etc. have capacitive mains filters, which can result in spurious results as the ‘mains filter’ (Suppressor) often consists of ‘Y’ connected capacitors, i.e. separate capacitors between live and earth, and neutral and earth which will be detected under an AC test voltage. Both wiring diagrams show this type of ‘mains filter’ configuration.

In addition if we for now ignore the mains filter aspect to obtain a figure of higher than 3.5mA leakage (fail) on these types of tests the insulation of the appliance and/or its components would need to drop to below 65,000 ohms (65 Kohms) when a figure of a minimum of 2,000,000 ohms (2Megohms) is generally required to be classed as meeting safety standards. So this leaves some questions to ask?

- There are many other appliances that utilise ‘double pole’ switching and capacitance mains filters.

- Are you aware of these features?

- More importantly is the person charged with PAT testing your appliances aware?

- Did your PAT testing course cover major appliances and such issues?

- Does your PAT test meter have the long ‘Run‘ type option?

- If so is it applied?

- If you do apply such tests do you know what the result provided mean?

- Do your test procedures allow extended time for ‘Run’ type testing i.e. fill and run the appliance?

This article is not designed to be a substitute for gaining the required product knowledge to safely test major appliances it has been written to highlight and promote discussion about the safety testing of appliance that have undergone refurbishing/recycling processes and the weakness of relying on simple PAT testing procedures without in-depth knowledge of product.

It is not simply a matter of viewing a circuit diagram of an appliance to work out if extended testing is required or not as appliance manufacturers in general are loath to provide such technical information to ‘third parties’. Even when technical information is available it often does not show in any great detail the full working aspects of their circuit boards (often just an overview as in the diagrams used in this article which are extracts from appliance technical manuals).